Mar

09

PVD VS. POWDER COATING – WHAT IS THE DIFFERENCE?

- March 9, 2022

- 0 Comment(s)

PVD vs. Powder Coating

What is the difference between PVD and Powder Coated Items?

Estimated reading time: 1-2 minutes

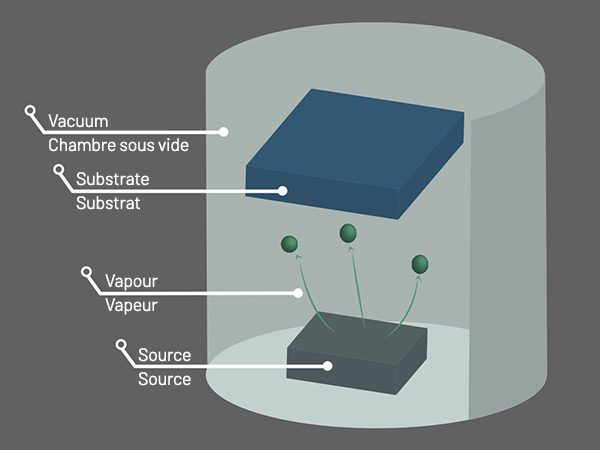

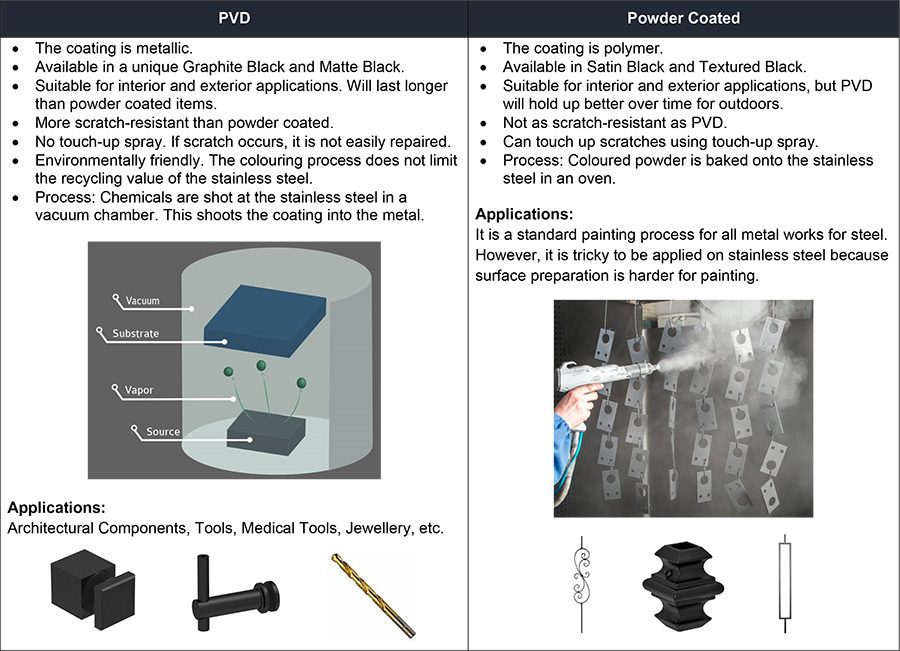

PVD

Photo courtesy of TennMax America. Translation by Euro.

FEATURES:

- The coating is metallic.

- Available in a unique Graphite Black and Matte Black.

- Suitable for interior and exterior applications. Will last longer than powder coated items.

- More scratch-resistant than powder coated.

- No touch-up spray. If scratch occurs, it is not easily repaired.

- Environmentally friendly. The colouring process does not limit the recycling value of the stainless steel.

- Process: Chemicals are shot at the stainless steel in a vacuum chamber. This shoots the coating into the metal.

APPLICATIONS:

Architectural Components, Tools, Medical Tools, Jewellery, etc.

Powder Coating

Photo courtesy of Coatmaster.

FEATURES:

- The coating is polymer.

- Available in Satin Black and Textured Black.

- Suitable for interior and exterior applications, but PVD will hold up better over time for outdoors.

- Not as scratch-resistant as PVD.

- Can touch up scratches using touch-up spray.

- Process: Coloured powder is baked onto the stainless steel in an oven.

APPLICATIONS:

It is a standard painting process for all metal works for steel.

However, it is tricky to be applied on stainless steel because surface preparation is harder for painting.

DOWNLOAD (EN) | SAUVEGARDER (FR)

Click here for other kinds of technical information.

CONTACT US FOR INQUIRIES:

1 800.465.7143 (EN) • 1 866.574.7979 (FR)